Tritium plays a crucial role in radiation protection activities, providing key data for environmental monitoring and ensuring compliance with regulatory requirements. Measuring tritium levels is essential for evaluating the environmental impact of nuclear facilities.

Tritium bubblers are highly reliable tools, specifically designed to deliver accurate and consistent monitoring. This guide presents their key features, explains how they operate, and demonstrates why they are a trusted solution for regulatory-compliant tritium detection.

Tritium bubblers detect tritium in all its forms, including HTO and HT, with high precision, making them essential for monitoring low environmental concentrations.

The use of a tritium bubbler is widely recognized as a proven method due to its sensitivity and trapping efficiency. It complies with national regulations and meets ISO standards to ensure accurate monitoring of atmospheric discharges.

This guide outlines the essential characteristics of tritium bubblers, details their operation, and explains typical use cases—providing a clear understanding of their importance in regulatory tritium monitoring.

1. How is tritium measured?

Tritium is a radionuclide primarily produced in nuclear reactors. It can be released into the environment in two main forms:

HTO (tritiated water vapor)

HT (tritiated hydrogen gas)

To ensure monitoring in compliance with regulatory standards, several sampling techniques are available:

Condensation: This method captures tritiated water vapor through condensation. Natural condensation is simple but dependent on weather conditions and less suitable for short sampling periods. Artificial condensation enables short-duration sampling with lower detection limits than bubbling.

Molecular capture: This technique uses specific materials (such as sieves or resins) that can retain tritium. However, it often requires more complex post-sampling processing.

Bubbling: The most widely used method in France and many other countries. Air is passed through a liquid—typically water—to trap tritium. HTO is directly absorbed, while HT and other organic forms can be oxidized into HTO through catalysis.

2. What is a tritium bubbler?

A tritium bubbler is a device specifically designed to sample ambient air and measure tritium concentration after collection.

It operates on the principle of bubbling: air is drawn in and passed through a series of containers (bubbling pots) filled with water. Tritium in the form of HTO is directly absorbed by the water. For HT, a prior conversion is needed—an integrated catalytic furnace transforms HT into HTO, which can then be trapped in the water.

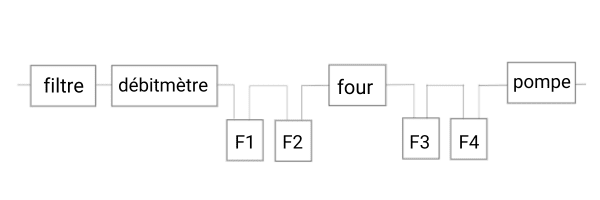

SDEC’s bubbler configuration allows for the distinction between these two tritium forms using a multi-pot system (e.g., pots 1 and 2 for HTO, pots 3 and 4 for HT). This setup enables differentiated analysis of tritium species.

The collected water is then analyzed using a liquid scintillation counter (such as the DPM7001, separate from the bubbler), which quantifies tritium concentration in Bq/m³.

This method offers several advantages:

- Direct analysis with no complex processing steps, since the SDEC bubbler traps tritium directly in water;

- Clear differentiation between HTO and HT based on the specific pots analyzed;

- Full compliance with current standards, including ISO 20045:2023;

- Flexible operation, suitable for weekly or monthly monitoring in environmental and regulatory contexts.

2.1 When is it used?

Tritium bubblers are used in a wide range of contexts where monitoring atmospheric emissions is required to meet regulatory standards or environmental tracking needs. Key areas of application include:

- Nuclear facilities (INB): Monitoring airborne tritium emissions to ensure compliance with thresholds defined by the INB decree, as mandated by the French Nuclear Safety Authority (ASN).

- Industrial use of tritium: Industries that use tritium in their processes (e.g., lighting, labeling) must monitor emissions to minimize environmental impact.

- Radioactive waste storage or treatment sites: Bubblers help measure atmospheric discharges to ensure tritium levels remain below authorized limits under controlled safety conditions.

- Research laboratories: Essential tools for scientific studies requiring precise tritium measurement in air, particularly in monitoring programs and experimental research.

- Specialized incineration plants: In certain cases, bubblers are used to track tritium levels in gaseous emissions from the incineration of tritium-containing waste, helping assess and mitigate environmental impact.

In all these applications, SDEC tritium bubblers ensure reliable traceability of measured concentrations and deliver actionable results for regulatory reporting and environmental control.

3. Benefits of Using a Tritium Bubbler

Tritium bubblers offer a reliable, proven solution for monitoring airborne tritium emissions. Their main advantages include:

- High sensitivity and precision, capable of detecting very low tritium concentrations;

- Direct sampling in water, eliminating the need for complex sample processing;

- Differentiation between HTO and HT, thanks to multi-pot configurations;

- Compliance with international standards, including ISO 20045:2023;

- Versatile use, suitable for routine regulatory checks and environmental monitoring.

These strengths make tritium bubblers a trusted choice for facilities that require accurate and compliant tritium measurement.

4. How Tritium Bubblers Work

Tritium bubblers operate on the principle of bubbling to trap different forms of tritium present in ambient air (HTO and HT). The system can be configured at the time of purchase based on specific needs—either for HTO capture only, or for combined HTO and HT capture with catalytic oxidation for accurate differentiation and compliance with monitoring requirements.

4.1 Simplified Diagram of a Tritium Bubbler

- Air Intake: Air is drawn in by a pump from an extraction duct and directed into the sampling circuit.

- Filtration and Flow Measurement: A dust filter removes solid particles, and a thermal mass flow meter measures the airflow, ensuring reliable readings independent of weather conditions.

- Tritium Capture via Bubbling: The air stream passes through a series of water-filled containers where HTO molecules dissolve. The multi-bottle setup ensures efficient capture of residual traces, in full compliance with regulatory sampling protocols.

- Catalytic Oxidation (for HT configurations): If tritium is present as HT (tritiated hydrogen), the air passes through a catalytic furnace that converts HT into HTO, which can then be captured in the water. This step is essential for complete tritium trapping.

- Storage and Analysis: The water collected in the bottles is then analyzed using liquid scintillation counting to accurately determine the tritium concentration in the sampled air.

5. The SDEC bubblers

5.1 The model MARC5000

The MARC5000 is designed to reliably sample tritium in the form of HTO for environmental monitoring and regulatory compliance. It operates without an oxidation module, focusing on the direct capture of tritiated water vapor present in the air.

The device features a factory-calibrated electronic flowmeter with automated flow control, ensuring stable and consistent sampling conditions. Its stainless steel circuit, paired with a durable diaphragm pump, guarantees long-term performance even in demanding environments.

A built-in cooling system maintains sampling temperatures within regulatory limits. The unit also includes both visual and remote alert systems to enhance operational safety. Fully compliant with applicable standards, including ISO 20045:2023, the MARC5000 is suitable for both continuous and spot tritium monitoring.

5.1 The model MARC7000

The MARC7000 is designed to sample tritium in all its forms: tritiated water vapor (HTO), tritiated hydrogen gas (HT), and even organic-bound tritium. It features four bubbling containers and an integrated catalytic furnace, enabling the conversion of HT into HTO for complete and efficient trapping.

The MARC7000 also includes all the functionalities of the MARC5000.

This configuration makes the device ideal for applications requiring comprehensive tritium measurement, particularly for regulatory monitoring of atmospheric emissions or targeted campaigns involving differentiated tritium analysis. The separation of bubbling bottles allows for clear distinction between the contributions of HTO and HT in the analyzed sample.

- Parameter Display and Data Logging:

Key parameters—such as flow rate, volume, temperature, and cooling—are displayed in real time for reliable monitoring, with options to export data for analysis and reporting. - Integrated Alarm System:

An audible alarm alerts users to anomalies, while recent events are logged via the RS232 output, enhancing traceability and ensuring quick response to any deviations.

| Tritium Bubbler – Marc 5000 | Tritium Bubbler – Marc 7000 | |

|---|---|---|

|

|

|

| Trapped form of tritium | HTO only | HTO, HT and OBT |

| Nº of pots | 2 | 4 |

| Trapping yield (HTO) | HTO = 99% +/- 7% | |

| Optimized trapping yield (HT) | ❌ | Furnace efficiency HT>HTO = 98 +/- 11% |

| T° furnace temperature | ❌ | 200 à 500°C |

| T° trapping solution | Optional | 7°C (for an ambient temperature of 20°C) |

| Weight (kg) | 27kg | 29kg |

| Max. Power (Watts) | 500 | 700 |

| Sampling Flow Rate (Standardized) | 10 à 50 Nl/h | |

| T° of use | +2 à +45 °C | |

| Storage Tº | -5 à +70 °C | |

| Adjusting the flow normalization temperature | 0 à +25ºC | |

| Display | Backlit LCD screen | |

| Dimensions L x H x P (mm) | 700 x 356 x 270 | |

| Footprint (mm) | 1000 x 600 x 530 | |

| Power Supply | 230 V / 50 Hz IEC plug (or 120 V / 60 Hz IEC plug) | |

| Electrical protection | differential circuit breaker (sensivity = 30mA) | |

| Air flow regulation | Automatic | |

| Other features | Reset function for duration and volume before re-sampling | |

| Audible alarm in the event of faults during sampling and display of the fault sequence on the screen | ||

| Memorization of the last 8 faults, data recoverable via the RS 232 output | ||

| Remote Fault Reporting via Dry Contact Output (Ethernet Optional): | ||

Conclusion

Measuring airborne tritium is a critical requirement for environmental monitoring around nuclear facilities. Among the various available methods, bubbling stands out as a proven, internationally standardized, and technically reliable solution.

Tritium bubblers capture tritium in the form of HTO—or in some configurations, all tritium forms after conversion into HTO. With robust design, integrated control systems, and direct compatibility with liquid scintillation analysis, they meet the expectations of both users and regulatory authorities.

The MARC5000 and MARC7000 models, developed by SDEC, exemplify this approach—delivering precise measurements, stable sampling conditions, and full compliance with regulatory standards. They are suitable for both continuous and spot monitoring, in France and worldwide.