EDP 9002 – Double Mast Electrodeposition Equipment

- SPACE-SAVING & ECONOMICAL DESIGN: Two measurement stations on a single base, ideal for laboratories with limited workspace. The EDP 9002 is more affordable than purchasing two EDP 7000 devices.

- TIME EFFICIENCY: Significant time savings when conducting multiple analyses.

- SYNTHETIC MATERIALS: The EDP is made solely from synthetic materials that perfectly resist the sometimes highly corrosive environments of research laboratories, thus ensuring a very long lifespan for the device.

- HIGH PRECISION: Ensures optimal trapping efficiency with regulated and constant direct current. The EDP is equipped with a polarity reverser for electrochemical stripping of the stainless steel pellet intended to receive the deposit, thereby ensuring perfect purity of the support.

- COOLING SYSTEM: Features high-flow air convection, preventing solution evaporation thanks to a solution cooling system with high-flow air convection.

- VERSATILE SETTINGS: Adjust the current intensity up to 5 Amperes and the electrode rotation speed with precision potentiometers and three sizes for solution containers.

- DIGITAL TIMER: Set the exact duration of electrodeposition with a digital display timer and an audible alarm.

- EASY TO USE: Quick assembly/disassembly of bottles and an internal container for accidental spills. Easy user maintenance of the device. Almost instantaneous assembly/disassembly of bottles.

- COLLABORATION WITH COGEMA: Designed in association with the leading French nuclear institute.

– Standard Model –

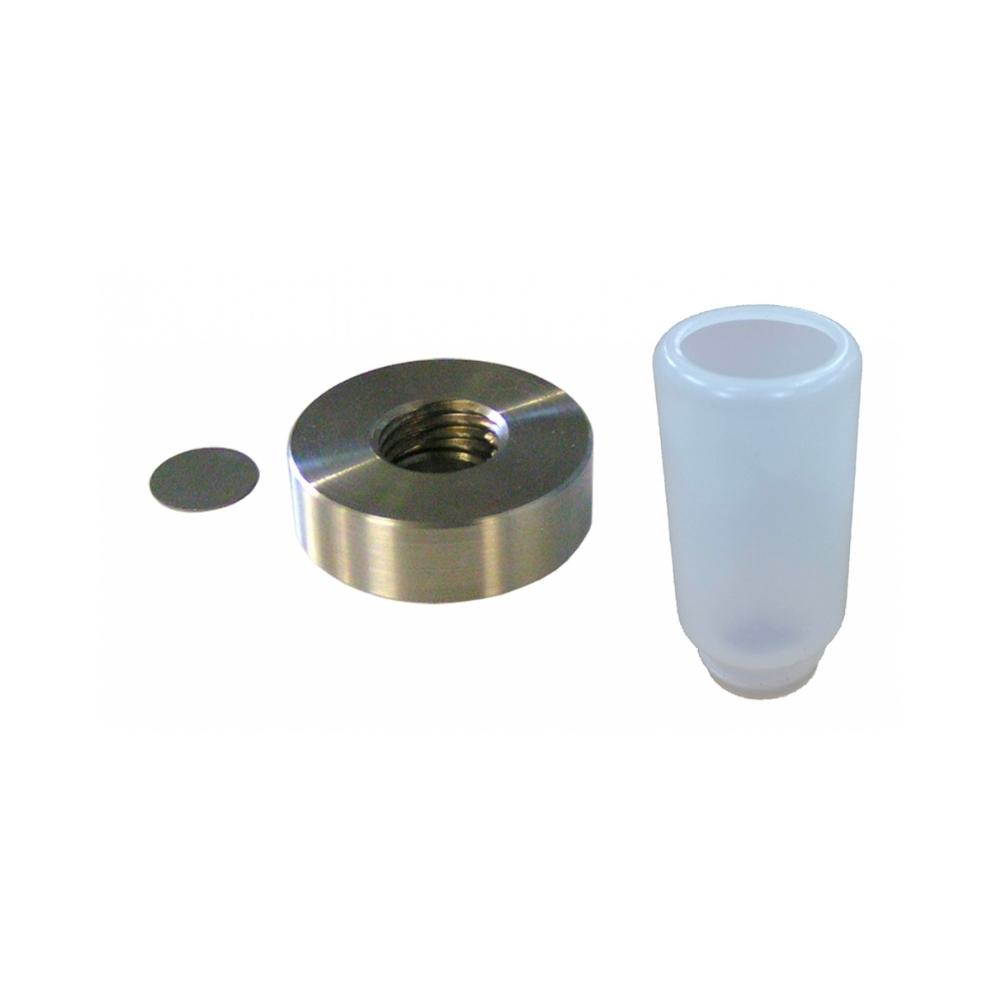

The base EDP 9002 comes with a Radiometer Analytical platinum PT XM 150 electrode, a bottle holder (specify the desired bottle size at the time of order) for each station, and standard high-flow ventilation.

Note that consumables are not included in the base model: sampling bottles, and stainless steel discs for electrodeposition.

– Operating Principle –

A platinum electrode is immersed in the solution from which radioisotopes are to be isolated.

This rotating electrode serves as the anode of a setup whose cathode is a stainless steel pellet located at the bottom of the electrolysis bottle.

A regulated and constant direct current will be applied to this solution, causing, through electrolysis (chemical decomposition of elements in the solution), the galvanic deposition of the present radioisotope(s).

– About SDEC –

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

– FAQ –

The EDP 9002 is designed for quick assembly and disassembly of bottles. It also includes an internal container for accidental spills, allowing easy user maintenance of the device. The design ensures almost instantaneous assembly/disassembly of bottles, making it very user-friendly.

The EDP 9002 features a high-flow air convection cooling system. This prevents the solution from evaporating due to the heat generated during the electrodeposition process, ensuring optimal trapping efficiency.

The EDP 9002 is equipped with a polarity reverser that allows for electrochemical stripping of the stainless steel pellet intended to receive the deposit. This ensures perfect purity of the support.

The EDP 9002 is entirely constructed from synthetic materials that perfectly resist the sometimes highly corrosive environments of research laboratories. This ensures a very long lifespan for the device.

The EDP 9002 offers significant time savings when conducting multiple analyses, thanks to its two measurement stations which allow for simultaneous operations.

The EDP 9002 has a space-saving design with two measurement stations on a single base, making it ideal for laboratories with limited workspace. Additionally, it is more cost-effective as the EDP 9002 is more affordable than purchasing two EDP 7000 devices.

Additional information

| Electrolysis Electrode | Flat platinum disc with screwable head |

|---|---|

| Electrolysis Current | Regulated and adjustable direct current from 0.1 A to 5 A |

| Current Regulation for Electrolysis | The intensity setting is continuous (resolution 0.02 A). In the "off" position or in the event of a power failure, the charging circuit is not traversed by any direct or reverse current |

| Electrode Rotation Speed | Continuously adjustable, from 10 to 600 revolutions per minute |

| Speed Regulation | Speed stability according to torque at ± 5% (time drift < 1 rpm) |

| Display in Revolutions per Minute | Stability: 1 revolution per minute |

| Display | Display of intensity and electrode rotation on an L.C.D screen |

| Timer | Passive timer from 1 minute to 9 hours with digital display and alarm buzzer |

| Cooling | High-flow ventilation, 1000 litres/min |

| Case | Case made of machined ARNITE |

| Mains Power Supply | 230 Volts 50 Hz, IEC type power cord |

| Maximum Power | 100 Watts |

| Weight | 10 kg |

| Footprint | L x H x P = 325 x 700 x 325 mm (monoposte) |

| Operating Tº | 0°C à + 45°C |

| Storage Tº | -25°C à + 70°C |

| Ruler | Adjustment of the electrode height on a graduated ruler |

| Front Panel | Scratch-resistant LEXAN type front panel |

Reviews

There are no reviews yet.