MARC 7000 – Tritium Bubbler: Atmospheric Monitoring System with 4 Pots (With Oven) for Trapping Tritium in HTO, HT, and OBT Forms

- EFFICIENCY: The MARC 7000 monitors atmospheric tritium, capturing vapor and gas, with oxidation in an oven.

- PERFORMANCE: 99% HTO trapping efficiency and 98% oven conversion efficiency for precise tritium monitoring.

- INTEGRATED ADVANCED FUNCTIONS: Offers adjustable airflow, real-time display of various parameters, automatic regulation, and default data storage. Designed for user-friendly operation and accurate readings.

- PERFORMANCE: Automatic air flow regulation, durable diaphragm pump, and 316L stainless steel circuit.

- INTEGRATED ADVANCED FUNCTIONS: Adjustable air flow, automatic regulation, real-time display, and anomaly storage.

- OPTIONS FOR ENHANCED FUNCTIONALITY: Cooling circuit, Ethernet connectivity, and alarms.

- VERSATILE APPLICATIONS: Suitable for the nuclear industry, research centers, waste storage, and laboratories.

- SUPPLIER CONFIDENCE: Officially supplied to major organizations such as IRSN, the French Navy, EDF, ANDRA, CEA, and internationally to IAEA and various nuclear power plants.

- CERTIFICATION: NF ISO 20045 & NF ISO 20041-1

| APPLICATIONS |

|

·Nuclear Power Plants ·Industrial Use of Tritium ·Research on the Impact of Different Contamination Levels ·Radioactive Waste Storage and Treatment Sites ·Laboratories ·Incinerators |

– Tritium Bubbler Comparison –

This comparative table details the specifics and characteristics of tritium bubbler systems, highlighting the MARC 5000 model with 2 pots (without oven) and the MARC 7000 model with 4 pots (with oven).

| Tritium Bubbler - Marc 5000 | Tritium Bubbler - Marc 7000 | |

|---|---|---|

|

|

|

| Trapped form of tritium | HTO only | HTO, HT and OBT |

| Nº of pots | 2 | 4 |

| Trapping yield (HTO) | HTO = 99% +/- 7% | |

| Optimized trapping yield (HT) | ❌ | Furnace efficiency HT>HTO = 98 +/- 11% |

| T° furnace temperature | ❌ | 200 à 500°C |

| T° trapping solution | Optional | 7°C (for an ambient temperature of 20°C) |

| Weight (kg) | 27kg | 29kg |

| Max. Power (Watts) | 500 | 700 |

| Sampling Flow Rate (Standardized) | 10 à 50 Nl/h | |

| T° of use | +2 à +45 °C | |

| Storage Tº | -5 à +70 °C | |

| Adjusting the flow normalization temperature | 0 à +25ºC | |

| Display | Backlit LCD screen | |

| Dimensions L x H x P (mm) | 700 x 356 x 270 | |

| Footprint (mm) | 1000 x 600 x 530 | |

| Power Supply | 230 V / 50 Hz IEC plug (or 120 V / 60 Hz IEC plug) | |

| Electrical protection | differential circuit breaker (sensivity = 30mA) | |

| Air flow regulation | Automatic | |

| Other features | Reset function for duration and volume before re-sampling | |

| Audible alarm in the event of faults during sampling and display of the fault sequence on the screen | ||

| Memorization of the last 8 faults, data recoverable via the RS 232 output | ||

| Remote Fault Reporting via Dry Contact Output (Ethernet Optional): | ||

– Operating Principle –

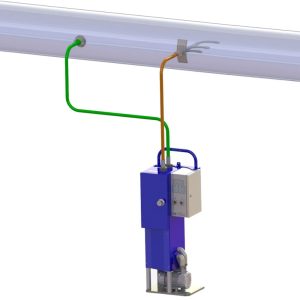

The MARC 7000 bubbler is used for monitoring atmospheric tritium concentration levels in vapor and gas form from chimneys, ventilation systems, hoods, premises, or the environment.

The MARC 7000 samples water vapor form of tritium (HTO) by bubbling in water in the first two pots, after particle filtration in the air. Gas form tritium (HT) or organic (OBT) is oxidized in an oven equipped with a catalyst, and then trapped by the same principle in the last two pots. The measured tritium activity is then reported to the volume of air passed through the device to determine the volumetric activity of tritium in the air (in Bq/m3 of air).

– Performance –

(CEA Marcoule test report June 2006)

– Air Flow Process –

A pre-filter paper at the entrance (∅ 45 mm) prevents the aspiration of dust, and the electronic flow meter is protected by Gortex® filters. The air flows in glass vials (250 ml capacity) through stainless steel air tubes. The airflow can be adjusted from 10 to 50 liters per hour, regulated by a certified flow meter.

– Official Supplier –

Various nuclear power plants in Europe and worldwide.

– About SDEC –

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

– FAQ –

Yes, you can customize the Marc 7000 according to your needs. You can add the following options to the bubbler: TOR Arte – Alarm Relay: Type T.O.R, JBUS Protocol, and Ethernet communication.

The device is equipped with a cooling circuit that maintains the trapping solution at an average temperature of 7°C (for an ambient temperature of 20°) and thus prevents the loss of the sample solution by evaporation. This option is essential for weekly or longer duration sampling.

Additional information

| pa_forme-tritium | 481, 480, 482 |

|---|---|

| Weight | 29 kg |

| Dimensions | L x H x P = 700 x 356 x 270 mm |

| Required Space | 1000 X 600 X 530 mm |

| Temp (Operating) | +2°C à +45°C |

| Temp (Storage) | -5°C à +70°C |

| Power | 700 Watts |

| Power supply | 230 V / 50 Hz IEC plug |

| Electrical protection | differential circuit breaker (sensivity = 30mA) |

| Applications | Incinerators, Industrial Use, Laboratories, Nuclear Power Plants, Radioactive Waste Storage and Treatment Sites, Research on the Impact of Different Contamination Levels |

| Extras | Aluminum alloy monocoque chassis |

| Housing paint | compliant with decontamination |

| Air flow regulation | adjustable from 10 to 50 SL/H |

| Display | Backlit LCD screen |

| Integrated system for reporting defects | Repeated acoustic signal with fault display on the screen. |

Reviews

There are no reviews yet.